- Low-temperature Vacuum Belt Dryer Series

- Belt Dryer Series

- Spray Dryer Series

- Flash Dryer and Airflow Dryer Series

- Fluidized Bed Dryer Series

- Vacuum,Conduction Dryer Series

- Box dryer series

- Mixing Equipment

- Granulating Equipment

- Drying Auxiliary Equipment

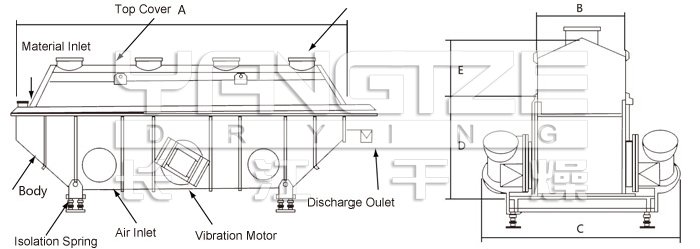

GZQ Vibration Fluidized Bed Dryer

Working Principle

Raw mate rial is feed into the machine from equipment inlet and move forward continuously along with the horizontal direction under vibratory power The hot air passes through fluidized—bed and exchange with raw materials' damp, then the wet air is dusted by cyclone separator and exhausted from air outlet,the d ried material is discharged through finished material outlet.

APPLICATION

This dryer is widely used for drying, cooling, wetting of the products in light industry, chemical industry, pharmaceutical industry, foodstuff, and etc.

Applicable Materials

Boric Acid, Borax, Dihydroxybenzene, Malic Acid, Maleic Acid, Monosodium Glutamate, Oxalate, Potassium, Permanganate, Sesame, Pentaerythritol, HPAM, Hypha Protein, Sodium Sulfate, Sodium Borate, Plastic Archon, Catalyst, Baking Soda, Detergent, Quartz Sand, Bean Pulp, Edible Sugar, Refine Salt, Bean, Seeds, Mining Slag, Activated Clay, Compound Fertilizer, and etc.

FEATURES

1. The vibration is created by vibrating motor which is stable in operation, easy for maintenance, low noise, and long service life.

2. The material is being heated evenly and the heat exchange is fully used which ensured high drying capacity. The energy consumption is 30% lower compare to the common dryers.

3.The adjustability of the dryer is good and it is widely used in different industries. The material thickness, moving speed inside the dryer, and amplitude can be adjusted.

4. The damage to the material surface is small so the dryer can be used for fragile materials. The irregular particles will not affect performance of the dryer.

5. A fully enclosed structure will effectively prevent cross contamination between the material and the air environment.

6. Multiple series connection is optional if the material contents high moisture and required high capacity; such as Polyacrylamide.

Technical Parameter

| Size / Model | A | B | C | D | E | F | Weight(kg) |

| GZQ3×0.30 | 3000 | 300 | 1350 | 900 | 430 | 1650 | 1250 |

| GZQ4.5×0.30 | 4500 | 300 | 1350 | 900 | 430 | 1650 | 1250 |

| GZQ4.5×0.45 | 4500 | 450 | 1550 | 950 | 430 | 1700 | 1670 |

| GZQ4.5×0.60 | 4500 | 600 | 1650 | 950 | 430 | 1700 | 1670 |

| GZQ6×0.45 | 6000 | 450 | 1650 | 950 | 430 | 1700 | 2100 |

| GZQ6×0.60 | 6000 | 600 | 1700 | 1000 | 500 | 1700 | 2410 |

| GZQ6×0.75 | 6000 | 750 | 1850 | 1000 | 600 | 1850 | 2840 |

| GZQ6×0.9 | 6000 | 900 | 2000 | 1000 | 600 | 1850 | 3160 |

| GZQ7.5×0.60 | 7500 | 600 | 1850 | 1000 | 600 | 1850 | 3200 |

| GZQ7.5×0.75 | 7500 | 750 | 2000 | 1000 | 600 | 1850 | 3600 |

| GZQ7.5×0.9 | 7500 | 900 | 2100 | 1000 | 600 | 1850 | 4140 |

| GZQ7.5×1.2 | 7500 | 1200 | 2500 | 1150 | 800 | 2050 | 5190 |

| Model |

Area of fluidized-bed (M2) |

Temperature of inlet air (oC) |

Temperature of outlet (oC) |

Capacity to vapor moisture (kg) |

Vibration motor | |

| Model | Power (Kw) | |||||

| GZQ3×0.30 | 0.9 | 70-140 | 40-70 | 20-35 | ZDS31-6 | 0.8×2 |

| GZQ4.5×0.30 | 1.35 | 70-140 | 40-70 | 35-50 | ZDS31-6 | 0.8×2 |

| GZQ4.5×0.45 | 2.025 | 70-140 | 40-70 | 50-70 | ZDS32-6 | 1.1×2 |

| GZQ4.5×0.60 | 2.7 | 70-140 | 40-70 | 70-90 | ZDS32-6 | 1.1×2 |

| GZQ6×0.45 | 2.7 | 70-140 | 40-70 | 80-100 | ZDS41-6 | 1.5×2 |

| GZQ6×0.60 | 3.6 | 70-140 | 40-70 | 100-130 | ZDS41-6 | 1.5×2 |

| GZQ6×0.75 | 4.5 | 70-140 | 40-70 | 120-140 | ZDS42-6 | 2.2×2 |

| GZQ6×0.9 | 5.4 | 70-140 | 40-70 | 140-170 | ZDS42-6 | 2.2×2 |

| GZQ7.5×0.60 | 4.5 | 70-140 | 40-70 | 130-150 | ZDS42-6 | 2.2×2 |

| GZQ7.5×0.75 | 5.625 | 70-140 | 40-70 | 150-180 | ZDS51-6 | 3.0×2 |

| GZQ7.5×0.9 | 6.75 | 70-140 | 40-70 | 160-210 | ZDS51-6 | 3.0×2 |

| GZQ7.5×1.2 | 9 | 70-140 | 40-70 | 200-260 | ZDS51-6 | 3.0×2 |

* The above is the largest evaporation.

Previous:None